Silmax 360°

Silmax, has recently developed the services Silmax 360° and 24h Service for end mills for ribs.

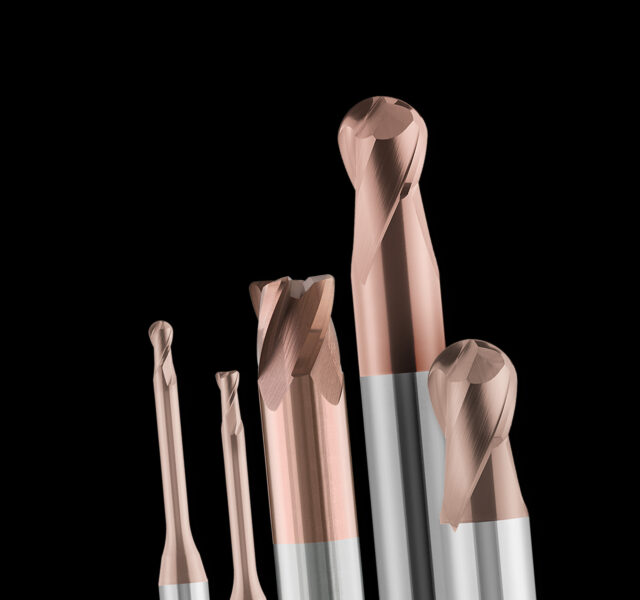

Silmax 360° represents a consulting service to help users choose the most appropriate machining strategies and the best-performing Silmax tools, with the new end-mill programme for machining “HRC” dies and molds, in cooperation with TopSolid.

Silmax intends to be a partner of reference for enterprises that manufacture dies and molds for all sectors. The technical experts of Silmax are able to assist customers in all machining stages from feasibility studies to CAD-CAM programming, to support them with innovative solutions, in reducing production costs and improving the quality standards of their finished products.

SILMAX 360°

Consulting service

Silmax 360° represents a consulting service to help users choose the most appropriate machining strategies and the best-performing Silmax tools, with the new end-mill programme for machining “HRC” dies and moulds, in cooperation with TopSolid.

Silmax intends to be a partner of reference for enterprises that manufacture dies and moulds for all sectors. The technical experts of Silmax are able to assist customers in all machining stages from feasibility studies to CAD-CAM programming, to support them with innovative solutions, in reducing production costs and improving the quality standards of their finished products.

Specialist technical support in the selection of the appropriate strategy for the machining and manufacturing of dies and molds.

Study and optimisation of tool paths. Design of the best performing tool. Use of the most advanced CAD/CAM systems.

Creation of a database regarding direct experiences with end users, at the disposal of all customers for information on the various types of machining, with new strategies and optimizations.

Study and creation of ISO programmes for use on the main machine tools, for specific applications according to the required, different types of machining.

Analysis, testing and optimisation of current strategies and proposal of the best performing tool with the most adequate CAM path.

24h Service

The 24h Service makes all the end mills for ribs in the catalogue available in any adjusted size within 24 hours from the order date.

PVD Coatings

Relying on the experience gained during its thirty-year partnership with Oerlikon Balzers, in 2013 Silmax opened a new factory dedicated to PVD coating (physical vapour deposition) in its premises of Lanzo Torinese, with an INGENIA plant using Oerlikon Balzers technology and a robotised, ultrasound washing system.

Today, there is also a new PVD INNOVENTA kila unit, which, thanks to its advanced technology with latest-generation software and its high production capacity, reduces coating times, and to meet all needs for PVD coating of tools and for R&D activities.

Find out more about the available coatings by visiting the PVD Coatings page.