DNA Regeneration

Silmax keeps the DNA of its customers’ tools in its R&D Center. In this way, Silmax is able to recondition your tool based on the related technical drawings and give it a new life, allowing similar performances to those of a new tool.

Being aware of the importance of proposing a reliable and high-quality after-sale service, for several years Silmax has been offering its customers Silservice, a service of tool reconditioning, including re-sharpening, recoating and the special 4S-treatment, specially conceived by Silmax for a super-finishing of the tool cutting-edge surface.

The use of state-of-the-art CNC tool grinding machines, of micrometric measuring systems, of company-owned PVD-coating Balzers plants (INGENIA and the brand-new INNOVENTA kila), along with a proven experience in cutting-tool treatments, enable Silmax to guarantee top quality and high speed in processing cycles.

Options on request

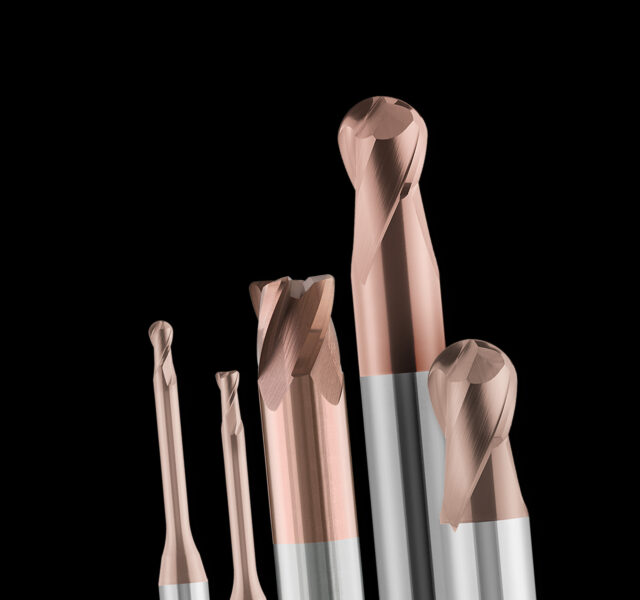

Silmax studies, develops and produces a wide range of special tools, both in carbide and high-speed steel, upon customer’s request or made to customer’s design.

Different options are available upon request: