Orthopaedics, implantology and dentistry

Silmax has developed a wide range of standard and special micro tools for the medical sector in general and, in particular, for orthopaedics, implantology and dentistry, where micro tools are used to machine materials, such as titanium, titanium or chrome-cobalt alloys, polyethylene and peel for inserts.

Silmax has always used CNC machines to guarantee a high level of precision and reliability when machining materials for the medical sector.

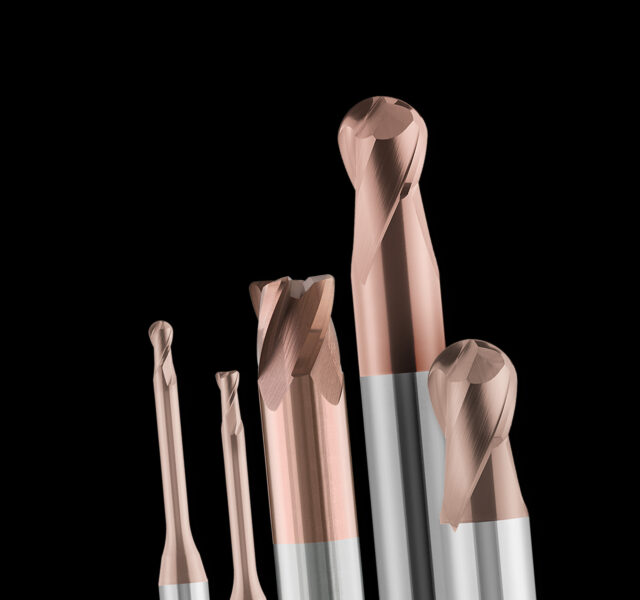

Our end mills for the medical sector undergo a PVD coating process, selecting non-toxic and biocompatible materials, allowing to obtain greater hardness, less friction and consequently better performance.

Spherical, cylindrical end mills and 2 or 3-flute micro end mills can meet high-precision requirements, where attention to detail is crucial in a sector like this.

PVD Coatings

Relying on the experience gained during its thirty-year partnership with Oerlikon Balzers, in 2013 Silmax opened a new factory dedicated to PVD coating (physical vapour deposition) in its premises of Lanzo Torinese, with an INGENIA plant using Oerlikon Balzers technology and a robotised, ultrasound washing system.

Today, there is also a new PVD INNOVENTA kila unit, which, thanks to its advanced technology with latest-generation software and its high production capacity, reduces coating times, and to meet all needs for PVD coating of tools and for R&D activities.

Find out more about the available coatings by visiting the PVD Coatings page.