Energy sector: oil and gas

In the energy sector, Silmax has been working for over twenty years, proposing standard and mostly special solutions, according to its customers’ requirements.

Our tools are particularly well-performing when used for machining – among other things – especially turbine rotors (slots and blade hub), blades (blade foot and complex shape machining), impellers, pumps, compressors.

The demand for products in the oil and gas sector will always be growing in the next years. To build these components, it will be essential to offer high-quality products, which will have to meet resistance and durability requirements, even in difficult environments, harder than those of other industrial sectors. Therefore, metallic materials are employed (stainless steels, titanium alloys, magnesium alloys, high-alloy steels, heat-resistant alloys) and continually developed ceramic materials.

For a long time, Silmax has been carrying out roughing, semi-finishing and finishing operations with special tools that are designed in-house for machining with stricter and stricter tolerances.

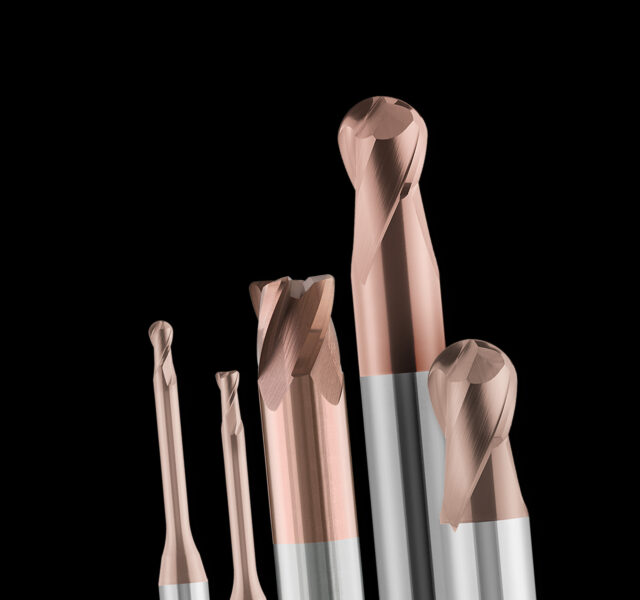

PVD Coatings

Relying on the experience gained during its thirty-year partnership with Oerlikon Balzers, in 2013 Silmax opened a new factory dedicated to PVD coating (physical vapour deposition) in its premises of Lanzo Torinese, with an INGENIA plant using Oerlikon Balzers technology and a robotised, ultrasound washing system.

Today, there is also a new PVD INNOVENTA kila unit, which, thanks to its advanced technology with latest-generation software and its high production capacity, reduces coating times, and to meet all needs for PVD coating of tools and for R&D activities.

Find out more about the available coatings by visiting the PVD Coatings page.