Gun drills and accessories

5001

Single-lip drill with brazed drill head for machining centres

5002

Single-lip drill with brazed drill head for drilling machines

5003

Single-lip drill with long brazed drill head for drilling machnes

5200

Rubber anti-vibrant drilling bushes D20

5201

Reinforced rubber anti-vibrant drilling bushes D20

5300

Rubber anti-vibrant drilling bushes D30

5301

Reinforced rubber anti-vibrant drilling bushes D30

5450

Rubber anti-vibrant drilling bushes D45

5451

Reinforced rubber anti-vibrant drilling bushes D45

5520

Vulkollan sealing disc D20

5532

Vulkollan sealing disc D32

5540

Vulkollan sealing disc D40

5590

Vulkollan sealing disc D90

Single-lip drill with brazed drill head for machining centres

Rubber anti-vibrant drilling bushes D45

Vulkollan sealing disc D32

Rubber anti-vibrant drilling bushes D45

Reinforced rubber anti-vibrant drilling bushes D30

Single-lip drill with brazed drill head for machining centres

Single-lip drill with brazed drill head for drilling machines

Reinforced rubber anti-vibrant drilling bushes D20

Single-lip drill with brazed drill head for drilling machines

Reinforced rubber anti-vibrant drilling bushes D30

Rubber anti-vibrant drilling bushes D30

Single-lip drill with brazed drill head for drilling machines

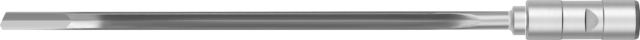

Highlights

A. High-quality hardened and tempered steel tube

B. V-shaped head seat

C. Micrograin k15 substrate optimal for a large variety of materials

D. Double hole for coolant starting from diameter 8

E. Reinforced cutting edge

Special gun drills

Solid-carbide, single-flute gun drills

The tool is made of a single lump of metal, composed of a small carbide cylinder that can be matched with a brazed steel clamping sleeve in the final part of the tool. This solution ensures particularly safe and efficient processes, as well as a longer tool life, thanks to the reduced torsional oscillations.

- Diameter range: 0.7 – 12.0 mm with 1/1000 mm increases

- Maximum length: 600 mm

- Tool usable length 80 – 100 x D

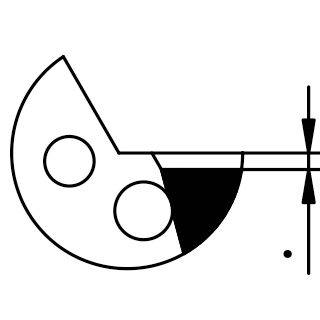

Single-flute gun drills with brazed drill head

It is the most commonly used solution in the market, developed with more elements brazed together. The tool is composed of a carbide drill head, a body (shank) and a clamping sleeve made of hardened and tempered steel. It is a very versatile type of tool, as it enables an endless number of customised versions in terms of diameters, lengths and clamping sleeves.

- Diameter range: 1.9 – 50.0 mm with 1/1000 mm increases

- Length up to 6000 mm

- Usable tool length: 40 – 50 x D

Our services

In addition to standard solutions, Silmax can also develop special solutions to meet your requirements, in consideration of the material to be machined and the particular drilling conditions. These solutions include the creation of specific geometries, step drills or reaming tools, with possibility of combining them with one of the numerous coatings we make in-house. All tools can be coated in-house by Silmax.

Silfast Service

Silmax offers its customers the possibility to have special tools with fast delivery time, 7 days from order receipt, for single-flute, brazed drills, with standard drill head and without coating.

- Available diameters

2.5 – 13.5 in 0.1mm steps. - Maximum length

1500 mm including clamping sleeve. - Typology of clamping sleeve

Download table. - Quantity

Up to a maximum of 5 pieces for each single diameter required.

The service entails an extra charge compared to products with standard delivery time. For all other diameters that are not included in this range, delivery times are standard.

Accessories

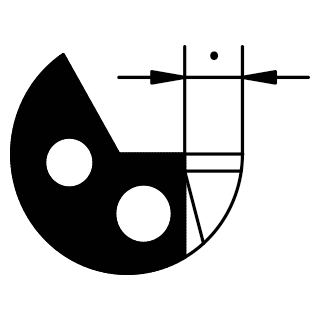

5.0 Anti-vibration drilling bushes standard version

5.1 Anti-vibration drilling bushes reinforced version

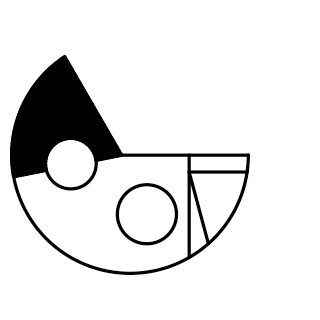

Vulkollan sealing discs

Technical information

Cooling lubricants

Guidelines for an appropriate choice of the products to be used and their optimal values of use.

A cooling lubricant is one of the most important elements in the use of gun drills: an accurate choice and a correct management can bring considerable advantages in terms of tool yield and performance.

The application of a well-performing filtration system is also recommended, as it is also fundamental for an optimal management of the whole process of deep-hole drilling.

Required conditions

Conditions required for an optimal drilling: neat oil or emulsified water with a concentration of 10-12%. In both cases, it is preferable to use products with specific additives for deep-hole drilling.

HM drills

Viscosity

7 – 10 mm2/s (Ø 0,8 – 2,0)

10 – 12 mm2/s (Ø 2,0 – 12,0)

Filter efficiency

5 – 10 μm

Brazed drills

Viscosity

10 – 20 mm2/s

Filter efficiency

10 – 20 μm

Surface finish

Thanks to its peculiar geometry, a gun drill enables to achieve a very high quality with regard to surface finish of the hole. This outcome can further be improved by using specific construction geometries. The table shows values that can be obtained by using a tool with a standard geometry.

| Tolerance | Twist drilling | Reaming | Broaching | Honing | Deep hole drilling | Arithmetical mean |

|---|---|---|---|---|---|---|

| μm | ||||||

| N12 | – | – | – | – | – | 50,000 |

| N11 | – | – | – | – | – | 25,000 |

| N10 | ● | – | – | – | – | 12,500 |

| N9 | ● | – | – | – | – | 6,300 |

| N8 | ● | ● | ● | – | – | 3,200 |

| N7 | – | ● | ● | ● | – | 1,600 |

| N6 | – | ● | ● | ● | ● | 0,800 |

| N5 | – | ● | ● | ● | ● | 0,400 |

| N4 | – | ● | – | ● | ● | 0,200 |

| N3 | – | – | – | ● | ● | 0,100 |

| N2 | – | – | – | ● | – | 0,050 |

| N1 | – | – | – | – | – | 0,025 |

Hole runout

Approximate runout values under deep-hole drilling conditions on machines with drill bush.

Working parameters for brazed gun drill

Working parameters for carbide gun drills

1. Cast iron

Vc=80 m/min

2. Light alloys

Vc=120 m/min

3. Aluminium

Vc=130 m/min

4. Steel <800N/mm²

Vc=85 m/min

5. Ferritic / Martensitic steel

Vc=55 m/min

6. Austenitic steel

Vc=45 m/min

7. Steel <1300N/mm²

Vc=70 m/min

8. Titanium

Vc=40 m/min

9. Austenitic steel

Vc=40 m/min

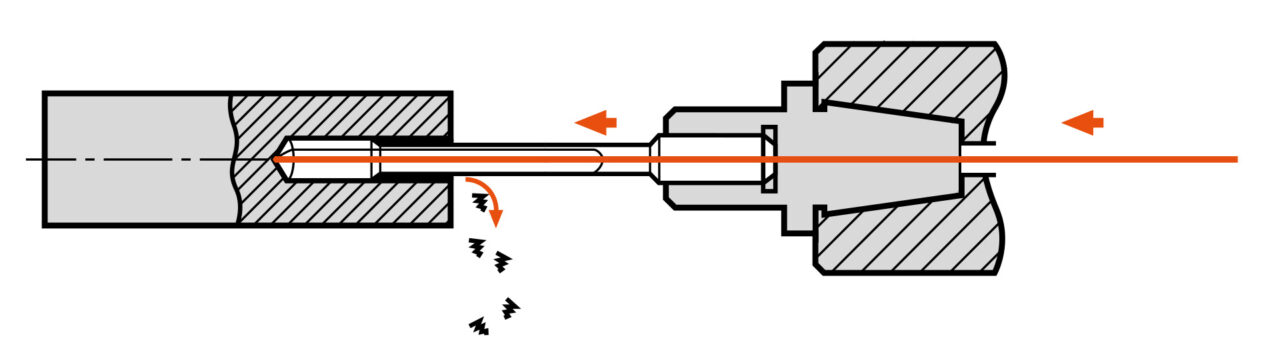

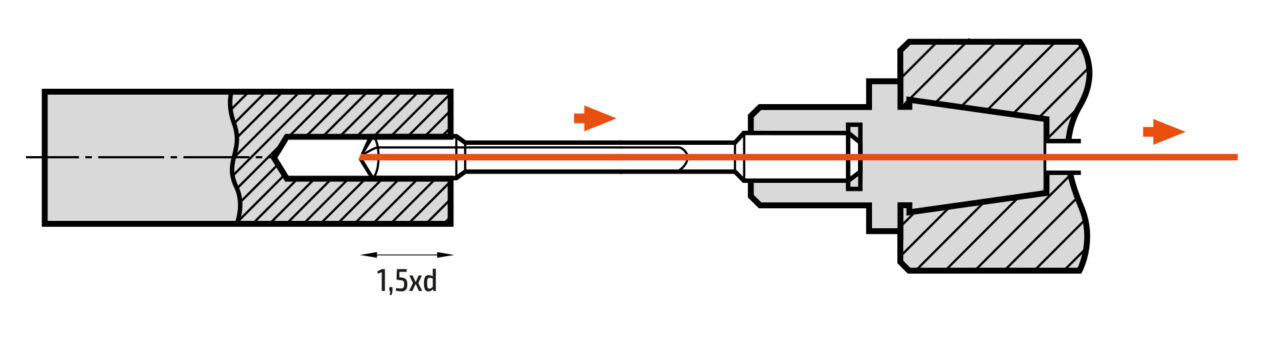

Drilling with pilot drill

1. Execution of pilot holes

We recommend the use of Silmax carbide drills Art. 3031A. Depth required for pilot hole: 1.5 x D.

2. Entry into pilot holes and drilling cycle

Enter with gun drill on spindle rotating in the counter-clockwise direction at a maximum of 100 rpm and F 1000mm/min. Set up at +5mm from the end of pilot hole and start coolant. Reverse the direction of rotation and execute drilling cycle according to working parameters.

3. Exit from hole

At the end of the cycle, move tool back to the starting point at F5000 mm/min, reverse rotation and exit at 100 rpm and F1000 mm/min.

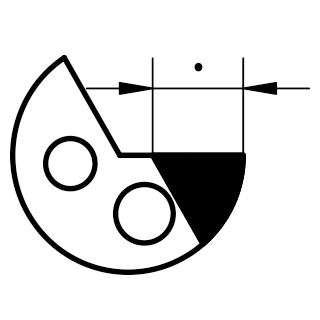

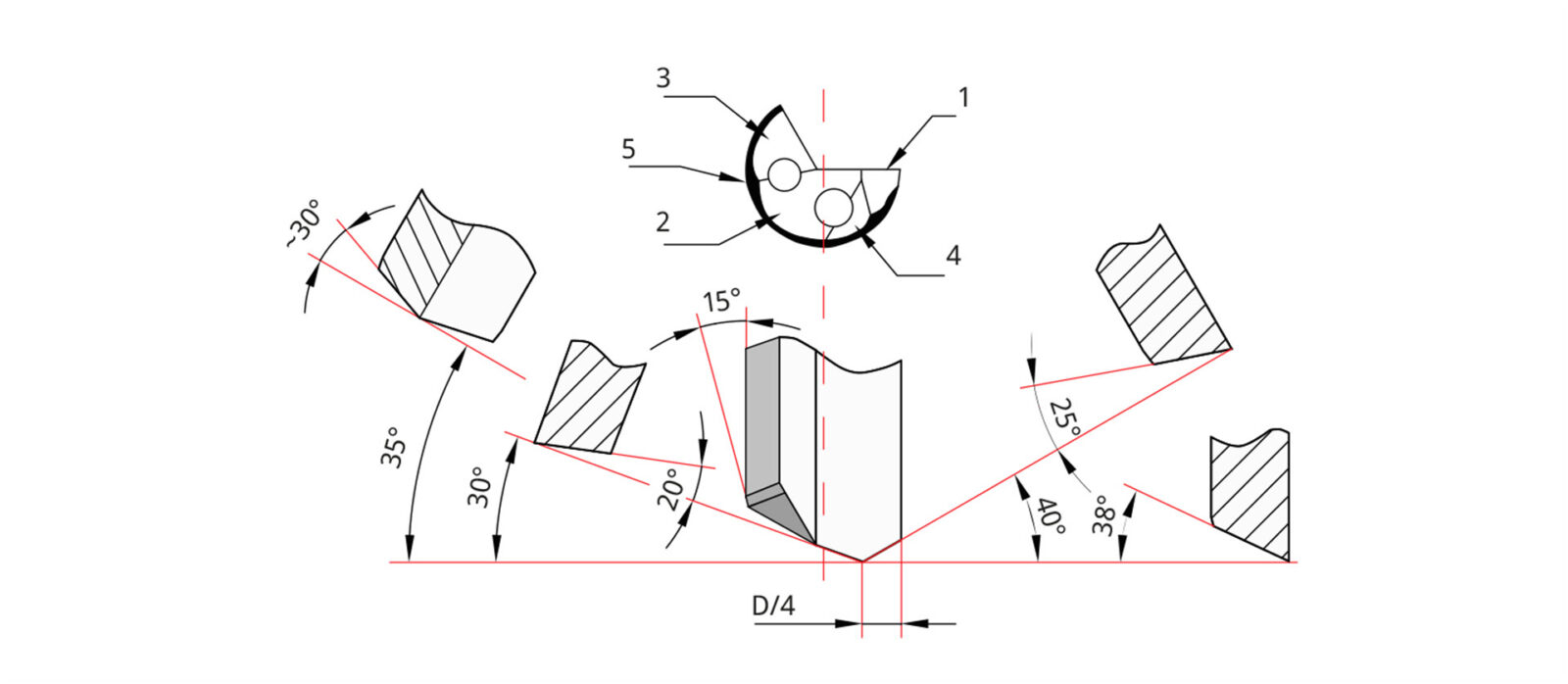

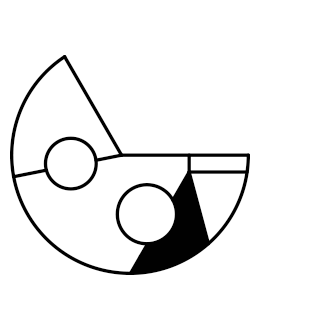

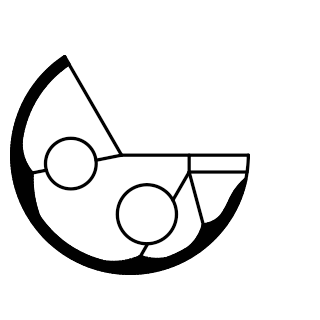

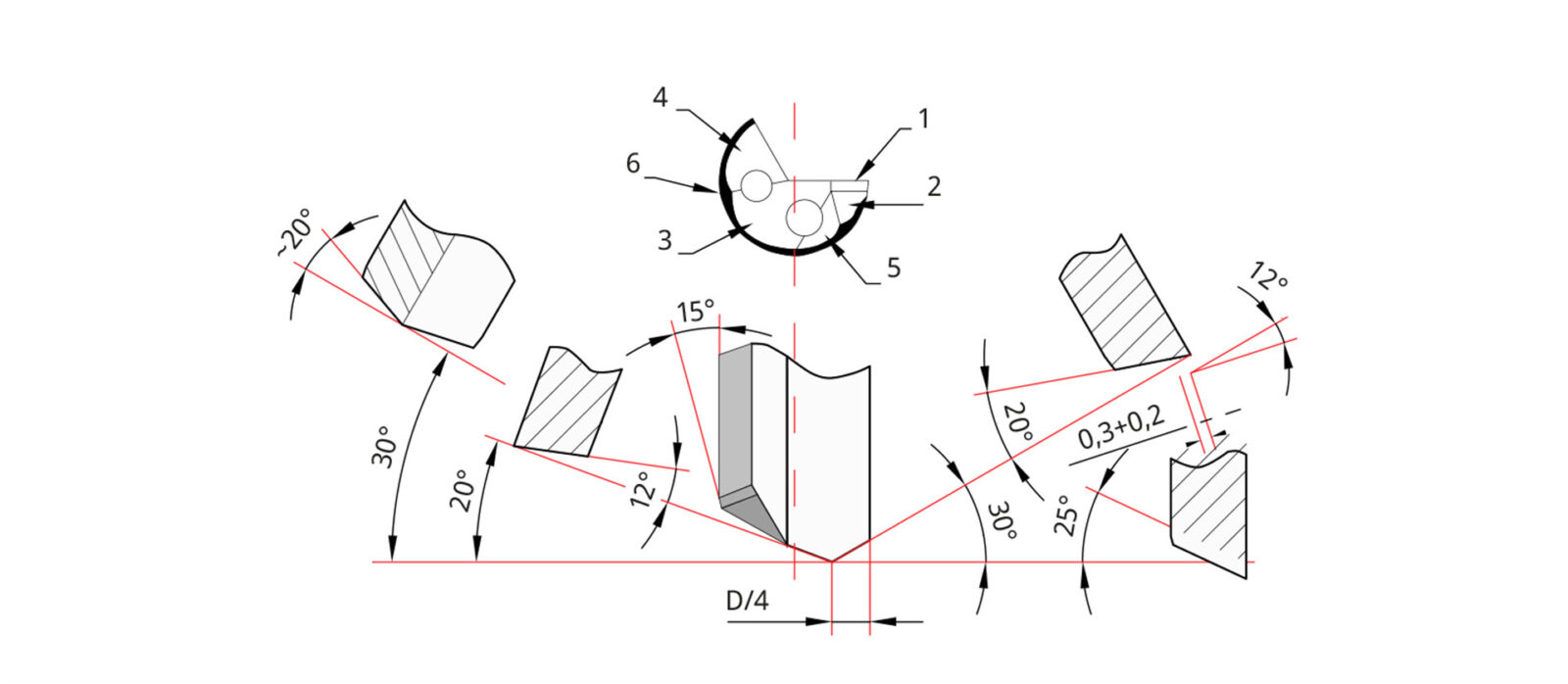

Cutting-edge geometry

La geometria standard Silmax è stata appositamente studiata per permettere di forare un ampio spettro di materiali con risultati ottimali. Tuttavia nelle situazioni particolari come per esempio materiali a truciolo lungo o difficilmente truciolabili, siamo in grado di realizzare soluzioni specifiche di geometria intervenendo su forma e affilatura oppure con eventuale creazione del romitruciolo sul filo tagliente. Nelle fasi di riaffilatura dell’utensile si consiglia di rispettare le indicazioni riportate nelle tabelle presenti. Un utensile accuratamente affilato sarà sempre al massimo delle prestazioni.

Standard grind section for single-lip drills up to 5 mm

Step 1

Axis A: 40°

Axis B: +25°

Axis C: +12°

Meas.: > D/4

Step 2

Axis A: 30°

Axis B: +20°

Axis C: -7°

Meas.: D/4

Step 3

Axis A: 35°

Axis B: +20°

Axis C: +55°

Meas.: –

Step 4

Axis A: 0°

Axis B: +38°

Axis C: 0°

Meas.: –

Step 5

Twist the single-lip drill lightly around the circumference

without damaging the guide chamfer.

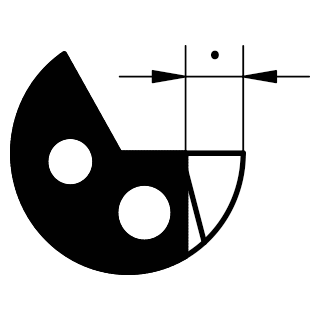

Standard grind section for single-lip drills with Ø = 5 to 30 mm

Step 1*

Axis A: -30°

Axis B: +12°

Axis C: +5°

Meas.: > D/4

Step 2*

Axis A: 30°

Axis B: +20°

Axis C: +6,5°

Meas: 0,3…0,5

Step 3

Axis A: +20°

Axis B: +12°

Axis C: -5°

Meas.: D/4

Step 4

Axis A: 30°

Axis B: +12°

Axis C: +55°

Meas.: –

Step 5

Axis A: 0°

Axis B: +25°

Axis C: -5°

Meas.: –

Step 6

Twist the single-lip drill lightly around the circumference without damaging the guide chamfer.

(*) Set Axis C such that the chamfer during the second pass is parallel to the chip face. The width of the chamfer is the same as that of the circular grinding chamfer.

Clamping sleeves

Silmax can develop customised solutions based on a drawing or a sample supplied by customers.

Range of standard clamping sleeves

DM

IFE

IFA

IPFE

VDI

6535 HA

1835 E

6535 HE

6535 HB

6535 HB

Range of clamping sleeves for solid carbide drills

6535 PHA

6535 PHB

6535 PHE

1835 PFE

5320 TBN

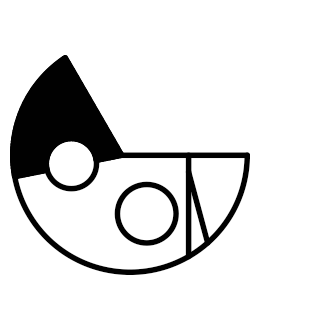

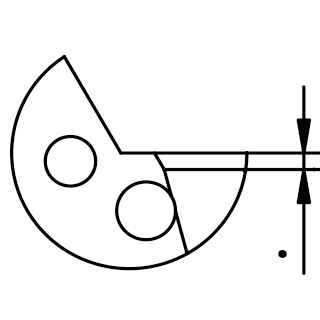

Standard contour shapes

First choice for drills with long drill head and optimised contour geometry for drilling under difficult conditions, such as intersections and situations where cooling lubricant is insufficient.

Special geometry specifically studied for drilling when high precision and high-quality surface finish are required. Available on request.

Standard geometry suitable for drilling most materials.

Specific geometry studied for soft materials, such as for example grey cast iron, graphite, etc. used when it is necessary to maintain reduced drilling tolerances. Available on request.